Gas Boosters

- Home

- /

- Products

Single Acting Single Stage Gas Boosters

The GB Series Gas Booster by Nidhi Automation is a flexible and efficient solution for delivering high-pressure gases. Designed for operations where high flow rates and compression ratios are not critical, the GB Series provides an economical method of pressure boosting using air drive.

| Model | Actual Ratio | Displacement Per Cycle -ml | Gas Piston Diameter -mm | Minimum Gas Inlet Pressure (Pi)-Bar | Maximum Gas Outlet Pressure (Po)-Bar | Po Formula (where Pa=air drive pressure) | Gas Inlet | Gas Outlet | Flow (where Pa = 7 Bar) – NL/min |

|---|---|---|---|---|---|---|---|---|---|

| NGB02T | 2.5:1 | 804 | 100 | 0 | 16.6 | 2.5Pa+Pi | NPT1/2″ | NPT1/2″ | 520 @ Pi=7 |

| NGB04 | 4:1 | 402 | 80 | 1.2 | 33.2 | 4Pa | NPT1/2″ | NPT1/2″ | 354 @ Pi=7 |

| NGB05T | 5:1 | 321 | 80 | 1.7 | 41.5 | 4Pa+Pi | NPT1/2″ | NPT1/2″ | 572 @ Pi=7 |

| NGB07 | 7:1 | 344 | 63 | 3.4 | 58.1 | 7Pa | NPT3/8″ | NPT3/8″ | 362 @ Pi=7 |

| NGB08T | 8:1 | 201 | 63 | 3.4 | 66.4 | 7Pa+Pi | NPT3/8″ | NPT3/8″ | 362 @ Pi=7 |

| NGB10 | 10:1 | 241 | 40 | 6.5 | 83 | 10Pa | NPT3/8″ | NPT3/8″ | 196 @ Pi=7 |

| NGB15 | 15:1 | 160 | 40 | 8.1 | 124.5 | 15Pa | NPT3/8″ | NPT3/8″ | 164 @ Pi=10 |

| NGB25 | 25:1 | 96 | 32 | 15 | 207.5 | 25Pa | NPT1/4″ | NPT1/4″ | 114 @ Pi=20 |

| NGB30 | 32:1 | 80 | 28 | 18 | 265.6 | 32Pa | NPT1/4″ | NPT1/4″ | 110 @ Pi=20 |

| NGB40 | 40:1 | 60 | 25 | 25 | 332 | 40Pa | NPT1/4″ | NPT1/4″ | 156 @ Pi=20 |

| NGB60 | 60:1 | 40 | 20 | 32 | 498 | 60Pa | NPT1/4″ | NPT1/4″ | 112 @ Pi=30 |

| NGB100 | 100:1 | 24 | 16 | 40 | 830 | 100Pa | NPT1/4″ | NPT1/4″ | 65 @ Pi=40 |

Type T is able to be turned into double-acting or two-stage units.

The maximum acceptable air drive pressure (Pa) is 8.3 Bar.. All model codes listed are standard. Oxygen gas service adds “OL” after the model codes.

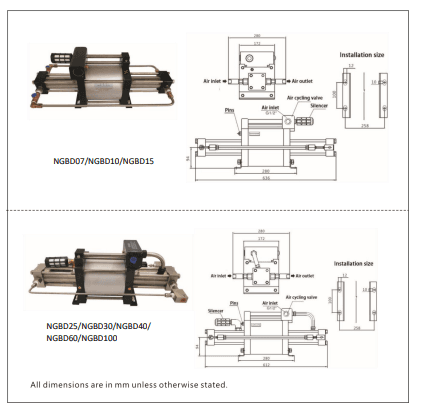

2NGBD Series - Double Acting Single Stage Double Air Drive Gas Boosters

The 2GBD Series gas booster pump from Nidhi Automations is a double air drive, single-stage gas booster pump. This series features two driving air pistons, each with a diameter of 160mm, effectively doubling the area ratio compared to standard GBD series gas boosters. The 2GBD Series is primarily used for high-pressure gas filling and pressure maintenance applications—such as high-pressure nitrogen plastic moulding, CO₂ systems, wire cables, foam production, and pressure testing.

| Model | Actual Ratio | Displacement Per Cycle -ml | Gas Piston Diameter -mm | Minimum Gas Inlet Pressure (Pi)-Bar | Maximum Gas Outlet Pressure (Po)-Bar | Po Formula (where Pa = air drive pressure) | Gas Inlet | Gas Outlet | Flow (where Pa = 7 Bar) – NL/min |

|---|---|---|---|---|---|---|---|---|---|

| 2GBD07 | 7:1 | 1378 | 80 | 3.4 | 66 | 7Pa + Pi | NPT3/8″ | NPT3/8″ | 774 @ Pi=7 |

| 2GBD15 | 15:1 | 643 | 56 | 3.4 | 99 | 15Pa + Pi | NPT3/8″ | NPT3/8″ | 614 @ Pi=7 |

| 2GBD30 | 32:1 | 321 | 40 | 7.5 | 265 | 32Pa + Pi | NPT3/8″ | NPT3/8″ | 530 @ Pi=10 |

| 2GBD50 | 50:1 | 193 | 32 | 25 | 415 | 50Pa + Pi | NPT3/8″ | NPT3/8″ | 353 @ Pi=25 |

| 2GBD60 | 65:1 | 160 | 28 | 25 | 539 | 65Pa + Pi | NPT3/8″ | NPT3/8″ | 327 @ Pi=25 |

| 2GBD80 | 82:1 | 120 | 25 | 40 | 680 | 82Pa + Pi | NPT1/4″ | HF4 | 385 @ Pi=40 |

| 2GBD150 | 150:1 | 74 | 20 | 60 | 1245 | 150Pa + Pi | NPT1/4″ | HF4 | 297 @ Pi=100 |

| 2GBD200 | 200:1 | 48 | 16 | 80 | 1660 | 200Pa + Pi | NPT1/4″ | HF4 | 187 @ Pi=100 |

All dimensions are in mm unless otherwise stated. The maximum acceptable air drive pressure (Pa) is 8.3 Bar. All model code listed are standard, Oxygen gas service add “OL” after the model codes. Hydrogen gas service add” H2″ after the model codes, CO2 gas service add “CO2” after the model codes.

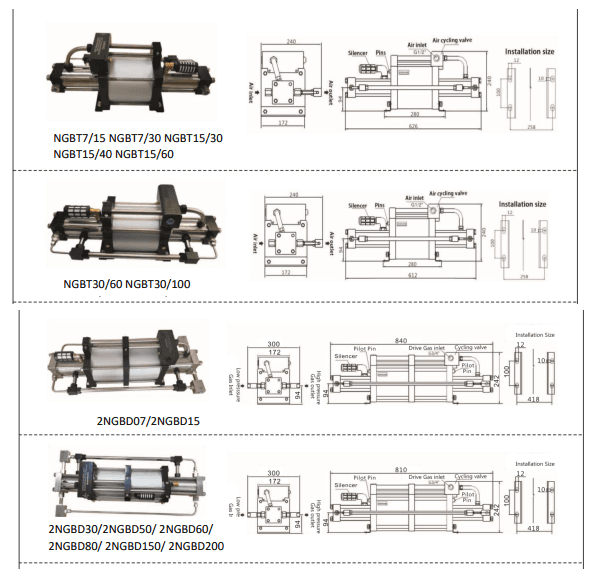

2NGBT Series - Two Stage Double Air Drive Gas Boosters

The 2GBT Two Stage Double Air Drive Gas Boosters from Nidhi Automation are two-stage units with two air drives connected in series. This effectively doubles the area ratio between the low-pressure air drive and the higher outlet pressure gas pistons. As a result, these boosters can achieve even higher gas outlet pressures. However, for efficiency, it is recommended not to exceed an overall compression ratio of 36:1.

These double air drive boosters offer all the benefits and features of the single-acting two-stage boosters.

The maximum acceptable air drive pressure (Pa) is 8.3 Bar.

All dimensions are in mm unless otherwise stated

All model code listed are standard, Oxygen gas service add “OL” after the model codes.

Hydrogen gas service add” H2″ after the model codes, CO2 gas service add “CO2” after the model codes.

| Model | Actual Ratio | Displacement Per Cycle -ml | Gas Piston Diameter -mm | Minimum Gas Inlet Pressure (Pi)-Bar | maximum Gas Outlet Pressure (Po)- Bar | Po Formula (where Pa=air drive pressure) | Gas Inlet | Gas Outlet | Flow(where Pa = 7 Bar) NL/min |

| 2NGBT7/15 | 15:1 | 689 | 80/56 | 3.4 | 125 | 15Pa+2Pi | NPT3/8″ | NPT3/8″ | 390@Pi=10 |

| 2NGBT7/30 | 32:1 | 689 | 80/40 | 3.4 | 240 | 32Pa+4Pi | NPT3/8″ | NPT3/8″ | 240@PI=10 |

| 2NGBT15/30 | 32:1 | 321 | 56/40 | 7 | 240 | 32Pa+2Pi | NPT3/8″ | NPT3/8″ | 286@Pi=10 |

| 2NGBT15/60 | 60:1 | 321 | 56/28 | 7 | 498 | 60Pa+4Pi | NPT3/8″ | NPT3/8″ | 165@Pi=10 |

| 2NGBT30/60 | 60:1 | 160 | 40/28 | 30 | 498 | 60Pa+2Pi | NPT3/8″ | NPT3/8″ | 455@Pi=40 |

| 2NGBT80/150 | 150:1 | 160 | 25/18 | 45 | 1200 | 150Pa+2Pi | NPT3/8″ | HF4 | 146@Pi=40 |

| 2NGBT80/200 | 200:1 | 80 | 25/16 | 60 | 1600 | 200Pa+3Pi | NPT3/8″ | HF4 | 70 @ pi=40 |