Pumps

- Home

- /

- Products

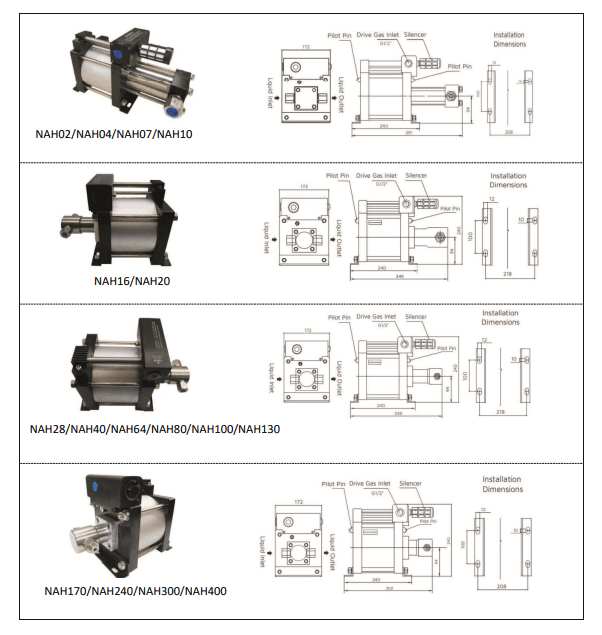

2NAH Series - 160mm Single Acting Double Air Drive Liquid Pumps

The 2AH series pumps use two 160mm double-acting air drives connected in series with a single liquid end. This effectively doubles the area of the air drive, thus allowing for very high nominal ratios—although with the lower flow output of a single-acting liquid pump. These pumps are generally applied when extremely high pressures are required for testing or pressing applications. Nidhi Automation offers these high-performance pumps for industries demanding precision and reliability under ultra-high pressure conditions.

The maximum acceptable air drive pressure (Pa) is 8.3 Bar.

All dimensions are in mm unless otherwise stated

All model code listed are standard, Oxygen gas service add “OL” after the model codes.

Hydrogen gas service add” H2″ after the model codes, CO2 gas service add “CO2” after the model codes.

| Model | Actual Ratio | Displacement Per Cycle -ml | Gas Piston Diameter -mm | Minimum Gas Inlet Pressure (Pi)-Bar | maximum Gas Outlet Pressure (Po)- Bar | Po Formula (where Pa=air drive pressure) | Gas Inlet | Gas Outlet | Flow(where Pa = 7 Bar) NL/min |

| 2NGBT7/15 | 15:1 | 689 | 80/56 | 3.4 | 125 | 15Pa+2Pi | NPT3/8″ | NPT3/8″ | 390@Pi=10 |

| 2NGBT7/30 | 32:1 | 689 | 80/40 | 3.4 | 240 | 32Pa+4Pi | NPT3/8″ | NPT3/8″ | 240@PI=10 |

| 2NGBT15/30 | 32:1 | 321 | 56/40 | 7 | 240 | 32Pa+2Pi | NPT3/8″ | NPT3/8″ | 286@Pi=10 |

| 2NGBT15/60 | 60:1 | 321 | 56/28 | 7 | 498 | 60Pa+4Pi | NPT3/8″ | NPT3/8″ | 165@Pi=10 |

| 2NGBT30/60 | 60:1 | 160 | 40/28 | 30 | 498 | 60Pa+2Pi | NPT3/8″ | NPT3/8″ | 455@Pi=40 |

| 2NGBT80/150 | 150:1 | 160 | 25/18 | 45 | 1200 | 150Pa+2Pi | NPT3/8″ | HF4 | 146@Pi=40 |

| 2NGBT80/200 | 200:1 | 80 | 25/16 | 60 | 1600 | 200Pa+3Pi | NPT3/8″ | HF4 | 70 @ pi=40 |

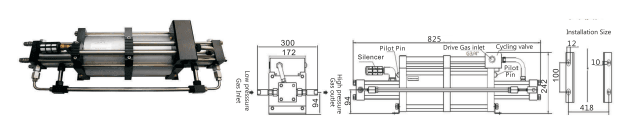

NGT Series 250mm DRIVEN Double Acting Liquid Pumps

The GT 250 series pumps are very high-flow pumps. Similar in concept to the smaller AT series pumps, they use a 250mm double-acting air drive with a liquid end connected to each side. These dual liquid ends make the pump double-acting by delivering high-pressure liquid on both strokes of the reciprocating air drive—making the GT series nearly twice as efficient as the GH series.These pumps can be supplied with interconnecting tubing that connects both liquid inlets to a common port and both liquid outlets to a common port, simplifying installation. GH pumps are generally used when more flow is needed than that delivered by the corresponding AH or AT units.

An important application for this series of air-driven liquid pumps is methanol injection and LPG transfer. Nidhi Automation offers the GT 250 series as a robust solution for high-demand fluid applications across critical industries.

| Model | Piston/Rod Diameter -mm | Flowper Cycle -ml | Liquid Inlet -NPT | Liquid Outlet -NPT | Maximum Output Pressure Bar@ Drive 8.3 Bar | ||||

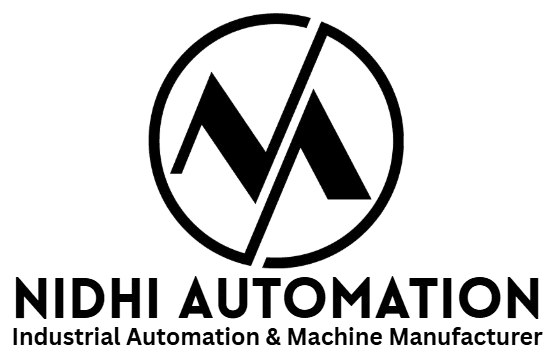

| NAH02 | 100 | 471 | NPT3/4″ | NPT3/4″ | 16.6 | ||||

| NAH04 | 80 | 402 | NPT3/4″ | NPT3/4″ | 33.2 | ||||

| NAH07 | 63 | 249 | NPT3/4″ | NPT3/4″ | 58.1 | ||||

| NAH10 | 50 | 157 | NPT3/4″ | NPT3/4″ | 83.0 | ||||

| NAH16 | 40 | 100 | NPT3/4″ | NPT3/4″ | 132.8 | ||||

| NAH20 | 35 | 76 | NPT3/4″ | NPT3/4″ | 166.0 | ||||

| NAH28 | 30 | 56 | NPT1/2″ | NPT1/2″ | 232.4 | ||||

| NAH40 | 25 | 39 | NPT1/2″ | NPT1/2″ | 332.0 | ||||

| NAH64 | 20 | 25 | NPT3/8″ | NPT3/8″ | 498.0 | ||||

| NAH80 | 18 | 20 | NPT3/8″ | NPT3/8″ | 664.0 | ||||

| NAH100 | 16 | 16 | NPT3/8″ | NPT3/8″ | 830.0 | ||||

| NAH130 | 14 | 12 | NPT3/8″ | NPT3/8 | 1079.0 | ||||

| NAH170 | 12 | 6 | NPT3/8″ | NPT3/8 | 1411.0 | ||||

| NAH240 | 10 | 4 | NPT3/8″ | NPT1/4″ | 1992.0 | ||||

| NAH300 | 9 | 3.8 | NPT1/4″ | HF4 | 2490.0 | ||||

| NAH400 | 8 | 3.0 | NPT1/4″ | HF4 | 3320.0 |

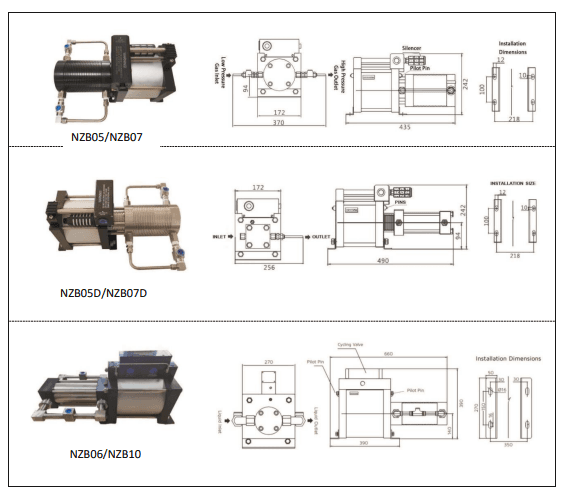

NZB Series 160mm Liquefied Gas Pumps

The 2AH series pumps use two 160mm double-acting air drives connected in series with a single liquid end. This effectively doubles the area of the air drive, thus allowing for very high nominal ratios—although with the lower flow output of a single-acting liquid pump. These pumps are generally applied when extremely high pressures are required for testing or pressing applications. Nidhi Automation offers these high-performance pumps for industries demanding precision and reliability under ultra-high pressure conditions.

| Model | Actual Ratio | Displacement Per Cycle (ml) | Minimum Inlet Pressure (Pi) – Bar | Maximum Outlet Pressure (Po) – Bar | Refrigerant Outlet Pressure Calculation Formula (Po) | Inlet | Outlet | 1g/cm standard density flow rate g/s |

|---|---|---|---|---|---|---|---|---|

| ZB05(-D) | 4:1 | 779 | 0.1 | 33.2 | 4Pa+Pi | NPT1/2″ | NPT1/2″ | 400 |

| ZB07(-D) | 7:1 | 473 | 3.4 | 56 | 7Pa+Pi | NPT1/2″ | NPT1/2″ | 280 |

| ZB10 | 10:1 | 402 | 3.4 | 83 | 10Pa | NPT3/8″ | NPT3/8″ | 160 |

| 4ZB06 | 6:1 | 1636 | 3.4 | 48 | 6Pa+Pi | PT1″ | PT1″ | 1600 |

| 4ZB10 | 10:1 | 981 | 3.4 | 83 | 10Pa+Pi | NPT3/4″ | NPT3/4″ | 900 |

Type D is isolated (completely isolated between the drive chamber and the boost chamber). The maximum acceptable air drive pressure (Pa) is 8.3 Bar.

| Working Medium type | Refrigerant types | Product name | Critical Pressure (MPa) | Critical Temperature (°C) | Boiling Point (°C) |

|---|---|---|---|---|---|

| Working Medium type | R12 | Methyl chlorofluoride | 4.14 | 111.97 | −29.8 |

| R22 | Monochlorodifluoromethane | 4.91 | 96.15 | −40.8 | |

| R32 | Difluoromethane | 5.808 | 78.52 | −51.7 | |

| R134A | Tetrafluoroethane | 4.07 | 101.1 | −26.5 | |

| R410A | R410A | 4.95 | 72.5 | 51.6 | |

| R407C | Difluoromethane | 4.619 | 86.74 | 36.1–43.4 | |

| R290 | Propane | 4.25 | 96.67 | 42.2 |

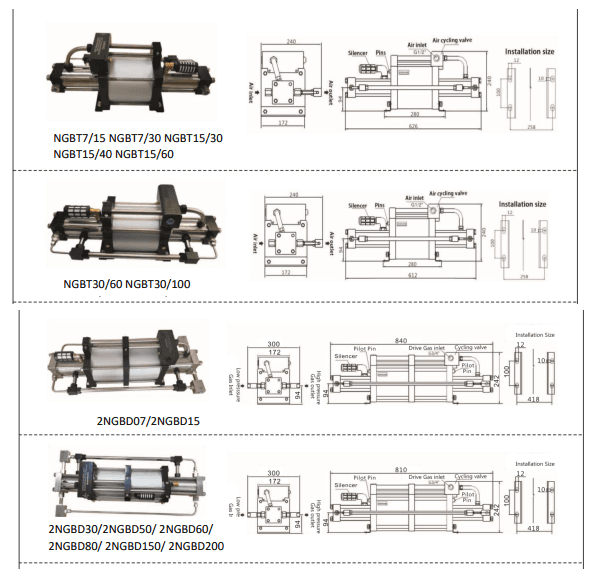

2NGBT Series - Two Stage Double Air Drive Gas Boosters

The 2GBT Two Stage Double Air Drive Gas Boosters from Nidhi Automation are two-stage units with two air drives connected in series. This effectively doubles the area ratio between the low-pressure air drive and the higher outlet pressure gas pistons. As a result, these boosters can achieve even higher gas outlet pressures. However, for efficiency, it is recommended not to exceed an overall compression ratio of 36:1.

These double air drive boosters offer all the benefits and features of the single-acting two-stage boosters.

The maximum acceptable air drive pressure (Pa) is 8.3 Bar.

All dimensions are in mm unless otherwise stated

All model code listed are standard, Oxygen gas service add “OL” after the model codes.

Hydrogen gas service add” H2″ after the model codes, CO2 gas service add “CO2” after the model codes.

| Model | Actual Ratio | Displacement Per Cycle -ml | Gas Piston Diameter -mm | Minimum Gas Inlet Pressure (Pi)-Bar | maximum Gas Outlet Pressure (Po)- Bar | Po Formula (where Pa=air drive pressure) | Gas Inlet | Gas Outlet | Flow(where Pa = 7 Bar) NL/min |

| 2NGBT7/15 | 15:1 | 689 | 80/56 | 3.4 | 125 | 15Pa+2Pi | NPT3/8″ | NPT3/8″ | 390@Pi=10 |

| 2NGBT7/30 | 32:1 | 689 | 80/40 | 3.4 | 240 | 32Pa+4Pi | NPT3/8″ | NPT3/8″ | 240@PI=10 |

| 2NGBT15/30 | 32:1 | 321 | 56/40 | 7 | 240 | 32Pa+2Pi | NPT3/8″ | NPT3/8″ | 286@Pi=10 |

| 2NGBT15/60 | 60:1 | 321 | 56/28 | 7 | 498 | 60Pa+4Pi | NPT3/8″ | NPT3/8″ | 165@Pi=10 |

| 2NGBT30/60 | 60:1 | 160 | 40/28 | 30 | 498 | 60Pa+2Pi | NPT3/8″ | NPT3/8″ | 455@Pi=40 |

| 2NGBT80/150 | 150:1 | 160 | 25/18 | 45 | 1200 | 150Pa+2Pi | NPT3/8″ | HF4 | 146@Pi=40 |

| 2NGBT80/200 | 200:1 | 80 | 25/16 | 60 | 1600 | 200Pa+3Pi | NPT3/8″ | HF4 | 70 @ pi=40 |